Machine Shop Services

Machine Shop Services

Our machine shop is incredibly well-equipped to help repair broken parts, reverse engineer and duplicate them and /or restore them to OEM specifications.

A Focus on Repair Parts

Our custom job shop team can work with customer supplied drawings, setup small batch manufacturing runs, and many times help you make, repair or restore parts faster than OEM lead times.

Strong Industry Experience

We’ve worked extensively with clients in the chemical, manufacturing and automotive industries as well as with wood mills, steel and aluminum manufacturing plants and mining operations.

Expedited Service

A key aspects of our machine shop that client’s value most is our high-quality and expedited service – with our emphasis on repair parts helping to keep their equipment and tooling up and running.

Experienced People

This is all possible due to the highly skilled and experienced people that are on our team in the machine shop. They bring to the table a very diverse range of experiences and strong set of capabilities.

High-End Tooling

To provide a foundation to those strengths, we have invested heavily in our machine shop’s tooling and capacity. As you see below, our CNC and manual tooling capabilities are well positioned to meet your machine shop needs.

Call Us Anytime

Call us to discuss an approach to your custom machining needs. We will put our knowledge to work for you and quickly guide you to a great solution.

MACHINE SHOP SERVICES

Custom Repair Parts

Restore to OEM Spec

Reverse Engineering

Custom Job Shop

Expedited Service

Experienced People

High-End CNC Machining

Hand Tool Machining

CNC Machining Capabilities

Fermat CNC Horizontal Boring Mill

The Fermat CNC Horizontal Boring Mill is a heavy-duty horizontal mill with a broad array of capabilities. It can perform machining from simple bores, drilling and tapping as well as complex shapes on parts and components with precision. With the built in rotary table, it can machine features at any angle with precision. It is used for manufacturing parts for heavy

machinery, aerospace, and other industrial applications.

This machine uses a CNC (Computer Numerical Control) system to automate and control the cutting and drilling operations. An operator can program a set of instructions, which the machine follows to perform the

desired operations. This makes the Fermat CNC Horizontal Boring Mill highly efficient and accurate.

The machine consists of a large 70.86” x 102.36” table that holds the workpiece, a 130 MM spindle along with a wide variety of cutting tools to perform different types of operations. It can perform drilling, boring, milling, tapping, and reaming operations of different sizes and shapes.

The Fermat CNC Horizontal Boring Mill is a versatile and powerful machine that can handle complex and precise machining operations with ease. Its high level of automation and accuracy makes it an essential tool in

modern manufacturing industries.

Unit Specs

- The new boring mill greatly expands our capacity and ability to handle large heavy pieces of material.

- It’s a Fermat WFT13 CNC Horizontal Boring Mill with 4 meters (157”) of table travel and 2-1/2 meters (98”) of vertical head travel.

- It supports 44,000 pounds of material.

- This is a tremendous step up in capacity and will let us do many more large jobs in a single configuration.

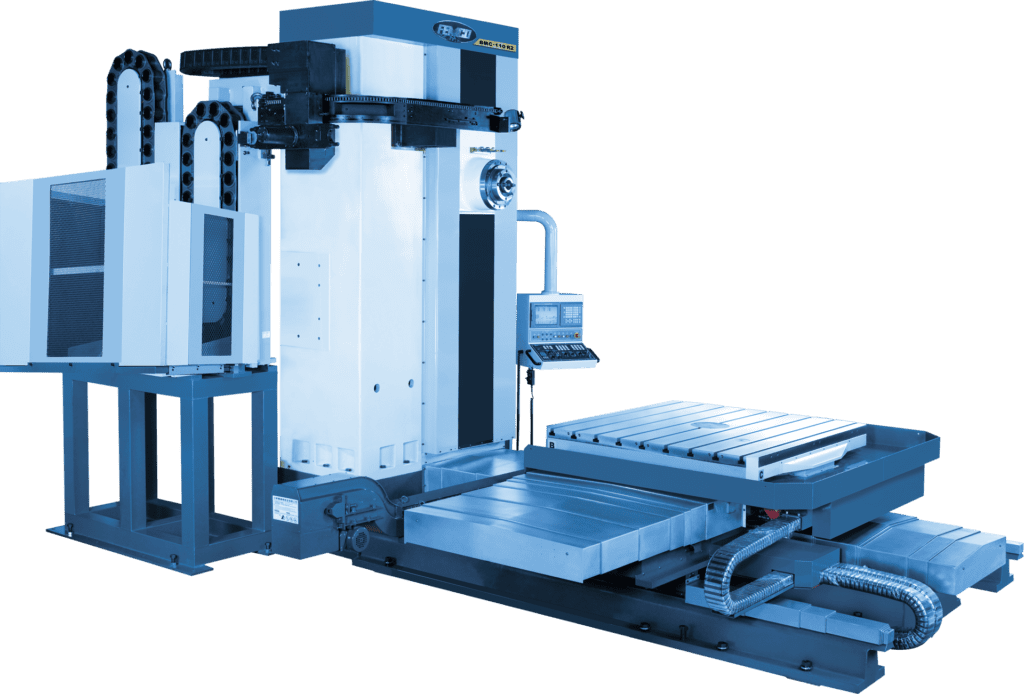

FEMCO BMC110R2 CNC Horizontal Boring Mill

The FEMCO BMC110R2 is a CNC horizontal boring mill designed for precision machining of large and heavy workpieces.

It features a rigid and robust construction with a cast iron bed, columns, and saddle for maximum stability and vibration damping.

The machine has a powerful 35 horsepower spindle motor that can operate at speeds ranging from 10 to 3000 RPM.

The CNC control system is user-friendly and intuitive, and the machine has a large worktable measuring 55 inches by 63 inches, which can support workpieces weighing up to 14,000 pounds.

Additionally, the machine has an automatic tool changer that can hold up to 60 tools and is equipped with a chip conveyor and coolant system.

Hwacheon ECOMIL 85VH CNC Vertical Machining Center

The Hwacheon ECOMIL 85VH is a high-performance CNC vertical machining center designed for precision machining of a wide range of materials.

It features a rigid and vibration-resistant construction with a one-piece bed, column, and saddle made of high-quality Meehanite casting for exceptional stability during heavy cutting operations.

The machine has a powerful 25 horsepower spindle motor with a maximum speed of 8,000 RPM and a rapid traverse rate of 48 meters per minute.

The CNC control system is user-friendly and allows for easy programming of complex machining operations. The machine also features a 30-tool automatic tool changer for efficient and reliable tool changes during machining operations.

The ECOMIL 85VH has a large worktable measuring 84.6″ x 33.5″ that can support workpieces weighing up to 11,000 lbs, and it is equipped with a chip conveyor and coolant system to manage the cutting fluids and chips generated during machining operations.

Overall, the Hwacheon ECOMIL 85VH is a versatile and reliable machining center that can handle a wide range of machining tasks with precision and efficiency.

Unit Specs

- X axis 78.8”

- Y axis 33.5”

- Spindle nose to table height 37”

- 11,000 lb. weight capacity

Milltronics CNC Knee Mills

Milltronics CNC Knee Mills are versatile and reliable machines designed for precision milling of small to medium-sized workpieces.

The machines feature a rugged and durable construction with a cast iron base, knee, and table that provide maximum stability and vibration damping during machining operations.

The machines are equipped with a powerful 3 horsepower spindle motor, which can operate at speeds ranging from 60 to 4200 RPM, and a quill travel of 5 inches, allowing for precise drilling and tapping operations.

The CNC control system is user-friendly and intuitive, and the machines can accommodate up to 16 tools in their automatic tool changers, providing flexibility and efficiency in machining operations.

The machines have a worktable measuring 10 inches by 50 inches or 10 inches by 54 inches, which can support workpieces weighing up to 1000 pounds. Additionally, the machines are equipped with a coolant system and a chip conveyor to manage the cutting fluids and chips generated during machining operations, ensuring that the machines operate efficiently and safely.

Overall, the Milltronics CNC Knee Mills are highly capable and reliable machines that can handle a variety of machining tasks with precision and efficiency, making them ideal for industries such as tool and die making, prototyping, and small batch production.

Northwood 125CS Five-Axis CNC Router

The Northwood 125CS 5 Axis CNC router is a powerful and versatile machine that is designed for precision cutting, shaping, and carving of various materials. It features a large working area and a 5-axis configuration that allows for intricate and complex designs to be created with high precision.

This router uses a computer-controlled system to automate and control the cutting operations, making it highly efficient and accurate. It can work with a wide range of materials, including wood, plastics, and non-ferrous metals, making it a versatile machine for many manufacturing applications. It boasts a 46” Z- Axis travel which allows for very tall workpiece machining.

The Northwood 125CS 5 Axis CNC router is equipped with advanced features, such as a high-speed spindle, precision ball screws, and linear guide rails, which ensure the highest level of accuracy and performance. It also features a user-friendly interface, which makes it easy for operators to program and control the machine.

Overall, the Northwood 125CS 5 Axis CNC router is an essential tool for modern manufacturing industries that require precision cutting, shaping, and carving of complex parts and components. Its advanced features and capabilities make it a valuable asset for any machine shop or manufacturing facility.

Unit Specs

- 60″ x 144″ single vacuum table

- Large working area for precision cutting and carving of materials

- 5-axis configuration for creating intricate and complex designs with high precision

- High-speed spindle for efficient cutting and shaping of materials

- Precision ball screws and linear guide rails for accurate and smooth movements

- User-friendly interface for easy programming and control of the machine

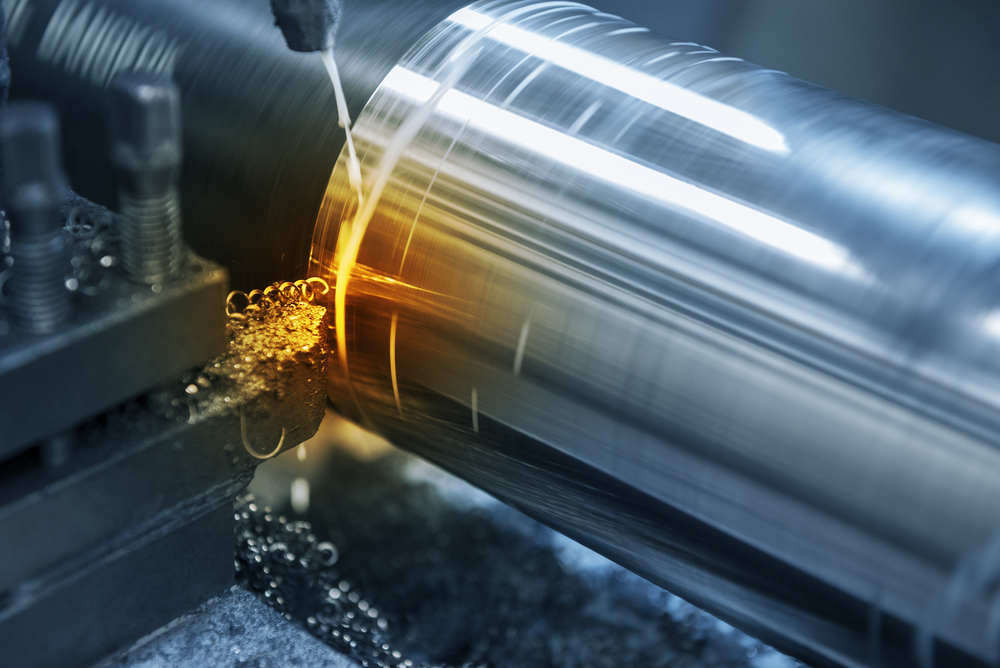

CNC Turning Capabilities

Hwacheon HiTech 850LYMC CNC Turning Center

The Hwacheon HiTech 850LYMC CNC Turning Center is a high-performance machine designed for precision turning of large and complex workpieces.

The machine features a rugged and durable construction with a one-piece bed and base made of high-quality Meehanite casting for maximum stability and vibration damping during machining operations.

The machine has a powerful 35 horsepower spindle motor, which can operate at speeds ranging from 20 to 1500 RPM, and a maximum turning diameter of 36.22 inches and turning length of 137.8 inches. The CNC control system is user-friendly and intuitive, enabling operators to program complex machining operations with ease.

The machine features a 12-station automatic turret with live tooling, allowing for efficient and reliable machining of complex workpieces. Additionally, the machine is equipped with a chip conveyor and coolant system to manage the cutting fluids and chips generated during machining operations, ensuring that the machine operates efficiently and safely.

Overall, the Hwacheon HiTech 850LYMC CNC Turning Center is a versatile and reliable machine that can handle a variety of turning tasks with precision and efficiency, making it ideal for industries such as aerospace, automotive, and heavy equipment manufacturing.

Milltronics ML18 CNC Lathe

The Milltronics ML18 CNC Lathe is a high-performance machine designed for precision turning of small to medium-sized workpieces.

The machine features a rugged and durable construction with a cast iron base, bed, and headstock that provide maximum stability and vibration damping during machining operations.

The machine has a powerful 7.5 horsepower spindle motor, which can operate at speeds ranging from 50 to 5000 RPM, and a maximum turning diameter of 14 inches and turning length of 20 inches.

The CNC control system is user-friendly and intuitive, enabling operators to program complex machining operations with ease. The machine features a 12-station turret with live tooling, allowing for efficient and reliable machining of complex workpieces.

Additionally, the machine is equipped with a chip conveyor and coolant system to manage the cutting fluids and chips generated during machining operations, ensuring that the machine operates efficiently and safely.

Overall, the Milltronics ML18 CNC Lathe is a versatile and reliable machine that can handle a variety of turning tasks with precision and efficiency.

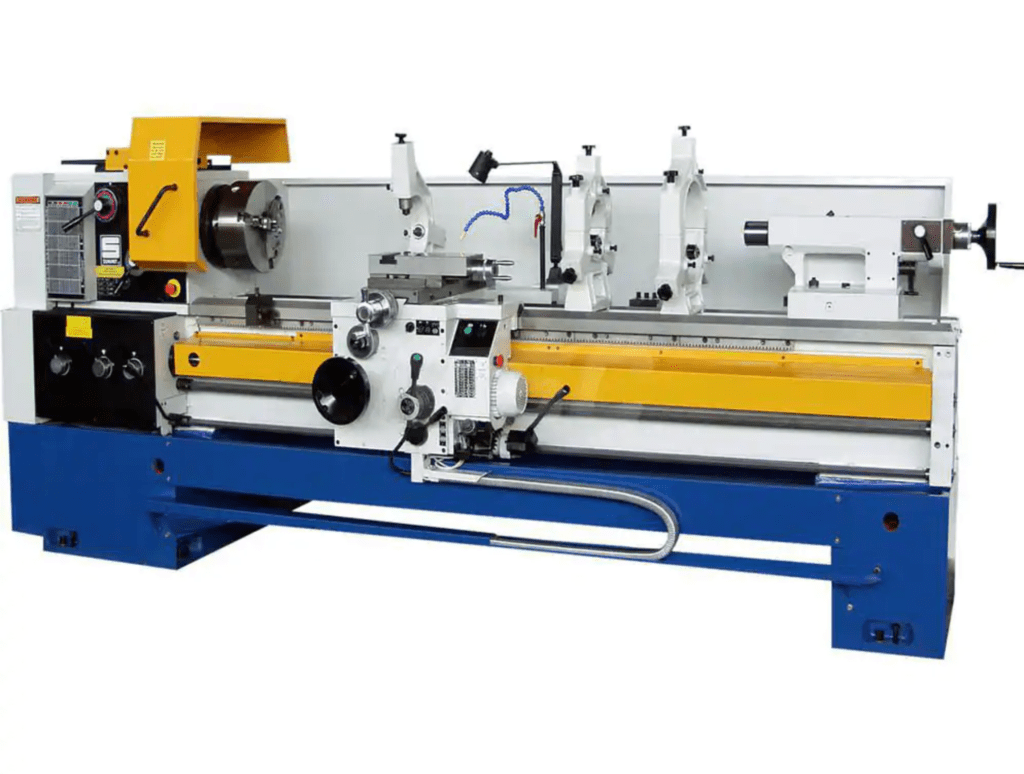

Summit Lathes

Summit lathes are versatile and reliable machines designed for precision turning of small to medium-sized workpieces.

The machines feature a rugged and durable construction with a cast iron base, bed, and headstock that provide maximum stability and vibration damping during machining operations.

Summit lathes come in various sizes and specifications, with spindle motors ranging from 5 to 25 horsepower and maximum turning diameters ranging from 14 inches to 40 inches.

The CNC control system is user-friendly and intuitive, enabling operators to program complex machining operations with ease. The machines feature a range of tool holders and cutting tools, allowing for a variety of turning operations, including facing, boring, threading, and drilling.

Additionally, the machines are equipped with a coolant system and a chip conveyor to manage the cutting fluids and chips generated during machining operations, ensuring that the machines operate efficiently and safely.

Overall, Summit lathes are highly capable and reliable machines that can handle a variety of turning tasks with precision and efficiency, making them ideal for industries such as tool and die making, prototyping, and small batch production.

Manual Turning – Special Capabilities

POREBA TCG-200 Engine Lathe

The POREBA TCG-200 Engine Lathe is a heavy-duty machine designed for precision turning of large workpieces.

The machine features a rugged and durable construction with a one-piece cast iron bed and headstock that provide maximum stability and vibration damping during machining operations.

The machine has a powerful 50 horsepower spindle motor, which can operate at speeds ranging from 2.8 to 560 RPM, and a maximum turning diameter of 2000mm and turning length of 12,000mm.

The machine is capable of threading, boring, drilling, and facing operations, and it is equipped with a 4-way rapid traverse tool post for efficient and reliable tool changes during machining operations.

Additionally, the machine is equipped with a chip conveyor and coolant system to manage the cutting fluids and chips generated during machining operations, ensuring that the machine operates efficiently and safely.

Overall, the POREBA TCG-200 Engine Lathe is a highly capable and reliable machine that can handle a variety of turning tasks with precision and efficiency, making it ideal for industries such as oil and gas, heavy equipment, and power generation.

Manual Machining Capabilities

Experienced Manual Machining

We offer a wide range of manual turning capabilities to handle a variety of machining tasks for large workpieces. Our machines can handle workpieces ranging from 13 inches to 79 inches in diameter and up to 19 feet in length.

Our experienced machinists can perform a variety of turning operations, including facing, boring, threading, and drilling, using different types of tool holders and cutting tools to accommodate different materials and geometries.

We take pride in our ability to produce high-quality parts with tight tolerances and surface finishes.

In addition to our advanced machining capabilities, we have a range of auxiliary equipment, such as overhead cranes and material handling systems, to facilitate the handling and transportation of large and heavy workpieces

Call Us

Tel: (304) 759-2150

Email Us

Opening Hours

Monday – Friday: 7:30 am – 4 pm EST